The production capacity of a typical brick making machine can vary depending on various factors such as the type of machine, its design, and the specific characteristics of the bricks being produced.

Here are some general guidelines for the production capacity of different types of brick making machines:

Manual Brick Making Machine: Manual brick making machines are usually designed for small-scale production. Their production capacity can range from a few hundred to a few thousand bricks per day, depending on the size and efficiency of the machine, as well as the skill and speed of the operator.

Semi-Automatic Brick Making Machine: Semi-automatic machines offer higher production capacities compared to manual machines. Depending on the specific model and configuration, they can produce several thousand to tens of thousands of bricks per day. The exact production capacity will depend on factors such as the machine’s speed, automation level, and the size and complexity of the bricks being produced.

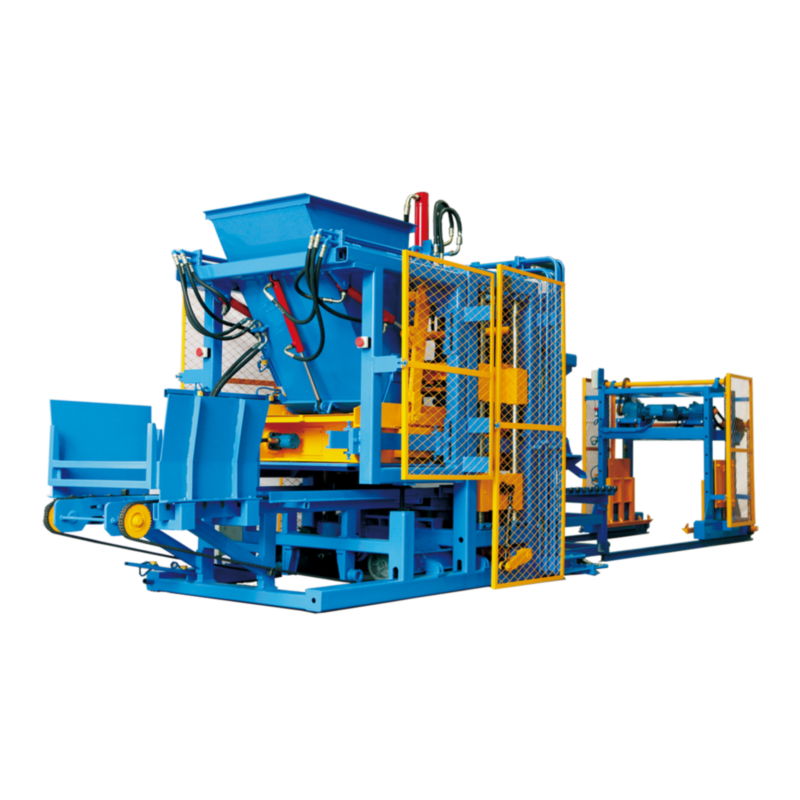

Fully Automatic Brick Making Machine: Fully automatic machines are designed for large-scale production and offer the highest production capacities. These machines can produce tens of thousands to hundreds of thousands of bricks per day. The production capacity depends on factors such as the machine’s speed, the number of molds or chambers it can accommodate, and the cycle time required for each production cycle.

It’s important to note that the production capacity mentioned above is a general range, and the actual production capacity can vary significantly based on the specific machine model, operator expertise, raw material availability, and other factors. Additionally, the production capacity can be influenced by the size, shape, and complexity of the bricks being produced.

When considering the purchase or use of a brick making machine, it is advisable to consult the manufacturer or supplier for specific information regarding the production capacity of the machine model you are interested in. They can provide more accurate and detailed information based on the specific features and specifications of the machine.

What are some factors that can affect the cycle time required for each production cycle?

The cycle time required for each production cycle in a brick making machine can be influenced by several factors. Here are some key factors that can affect the cycle time:

Machine Type and Design: Different types of brick making machines have varying designs and mechanisms, which can impact the cycle time. concrete block making machinery Fully automatic machines generally have faster cycle times compared to manual or semi-automatic machines due to their higher level of automation and efficiency.

Machine Speed and Capacity: The speed and capacity of the machine play a significant role in determining the cycle time. Machines with higher production capacities tend to have shorter cycle times as they can produce more bricks per unit of time. The design and engineering of the machine also affect its operational speed and efficiency.

Brick Size and Complexity: The size and complexity of the bricks being produced can affect the cycle time. Larger or more intricate brick designs may require additional time for molding, drying, or curing processes, which can extend the overall cycle time. Similarly, the presence of special features or patterns in the bricks can increase the time required for each production cycle.

Raw Material Preparation: The time required for raw material preparation can impact the overall cycle time. Processes such as material mixing, soaking, or conditioning may be necessary depending on the specific brick-making method and raw materials used. Efficient and well-organized material preparation can help minimize the cycle time.

Curing and Drying Time: If the brick making process involves curing or drying of the bricks, the duration of these stages can affect the overall cycle time. Curing or drying times depend on factors such as the type of bricks, environmental conditions, and curing methods employed. Faster curing or drying techniques can help reduce the cycle time.

Operator Skill and Experience: The proficiency and experience of the machine operator can influence the cycle time. Skilled operators who are familiar with the machine’s operation and processes can perform tasks more efficiently, resulting in shorter cycle times. Proper training and operator expertise are essential for maximizing production efficiency.

It’s important to note that the specific impact of these factors on the cycle time can vary depending on the machine model and manufacturer. When considering a brick making machine, it is advisable to consult the manufacturer or supplier for detailed information regarding the cycle time and factors that influence it.