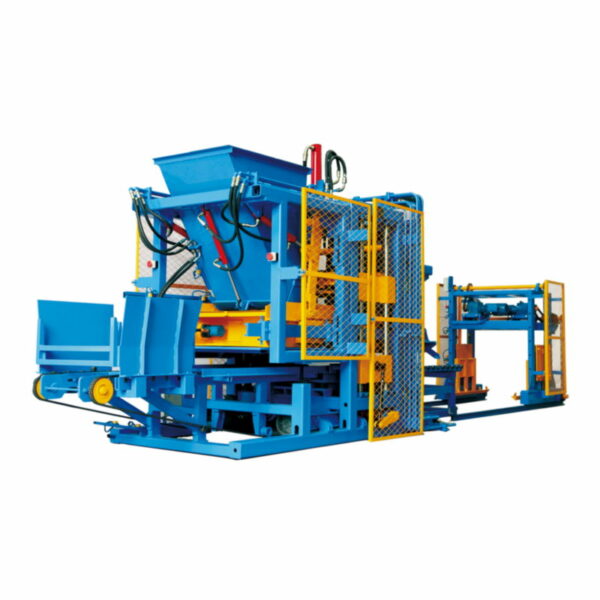

To ensure the proper functioning and longevity of a concrete block making machine, it is important to perform regular maintenance.

Here are some maintenance requirements for these machines:

Lubrication: The moving parts of the machine, such as the conveyor, mold, and mixing unit, should be lubricated regularly to reduce friction and prevent wear and tear. Use a recommended lubricant and follow the manufacturer’s instructions.

Cleaning: The machine should be cleaned regularly to remove any buildup of concrete or debris. Use a pressure washer or a hose to clean the machine, but take care not to damage any electrical components.

Inspection: Regular inspections of the machine should be performed to identify any signs of wear and tear or damage. Check for loose bolts, nuts, or screws and tighten them if necessary.

Electrical components: Check all electrical components, such as wires, switches, and motors, to ensure that they are functioning properly. Replace any faulty components immediately.

Replace worn-out parts: If any parts of the machine are worn out or damaged, they should be replaced immediately to prevent further damage to the machine.

Calibration: The machine should be calibrated regularly to ensure that it is producing blocks of the correct size and shape. Follow the manufacturer’s instructions for calibration.

Store the machine properly: When not in use, the machine should be stored in a dry and covered area to prevent rust or corrosion.

By following these maintenance requirements, you can ensure the proper functioning of your concrete block making machine and extend its lifespan. concrete block making machine It is important to follow the manufacturer’s instructions and recommendations for maintenance, and to seek professional help if you are unsure about any aspect of maintenance.

What should I do if I find a faulty electrical component?

If you find a faulty electrical component in your concrete block making machine, it is important to address the issue promptly to prevent any further damage or malfunction of the machine.

Here are some steps you can take if you find a faulty electrical component:

Turn off the power: Before attempting to replace or repair any electrical component, make sure to turn off the power to the machine to avoid any risk of electrical shock or injury.

Identify the faulty component: Use a multimeter or other electrical testing equipment to identify the faulty component. If you are unsure about how to do this, it is best to consult a qualified electrician or technician.

Replace the faulty component: Once you have identified the faulty component, replace it with a new one. Make sure to use the correct replacement part and follow the manufacturer’s instructions.

Test the machine: After replacing the faulty component, test the machine to ensure that it is functioning properly. If the machine still does not work, there may be other issues that need to be addressed.

Seek professional help: If you are unsure about how to replace or repair the faulty electrical component, or if the machine still does not work after replacement, it is best to seek professional help from a qualified technician or electrician.

By taking these steps, you can address any faulty electrical components in your concrete block making machine and ensure its proper functioning. It is important to prioritize safety when dealing with electrical components and to seek professional help if you are unsure about any aspect of repair or replacement.